We put the best steel in the world in your hands

HESA is proud to be an associate vendor of ArcelorMittal, the leading steel manufacturer that supplies the most important industries in the world.

Two big companies united for a common commitment: ensure the best quality

and service for projects that change our lives.

STEEL ROD

A-615 Grade 42

42,000 kg/cm2 of yield strength (Fy)

Availability

In diameters of 3/8” and 5/8”, we offer:

• Rolled steel rod.

• Straight rod, 12-meter long.

• Straight rod in special lengths.

In diameters of 3/4” and 1 ½”, we offer:

• Straight rod, 12-meter long.

• Straight rod in special lengths (on demand).

A-706 Grade 42

42,000 kg/cm2 of yield strength (Fy)

Only on demand

In order to find out the available diameters, contact us.

Grade 52

42,000 kg/cm2 of yield strength (Fy)

Only on demand

Availability

In diameters of 3/4” and 1 ½”, we offer:

• Straight rod, 12-meter long.

Advantages of using

Grade 52 rods versus Grade 42 rods.

The cutting-edge metalworking industry develops steel with Grade 52 and Grade 56 ASTM A 615 quality, as well as Grade 52 and Grade 56 ASTM A 706 (weldable) steel. This steel rod is mostly used in larger diameters, from ¾” to 1 ½”.

The great quality of a Grade 52 rod lies in the fact that the rod is 23.8% more resistant than a Grade 42 rod, and it allows savings of 10% in volume.

Time can also be saved as you will have fewer bars to prepare and assemble.

ROD PREPARATION

Customized to your needs.

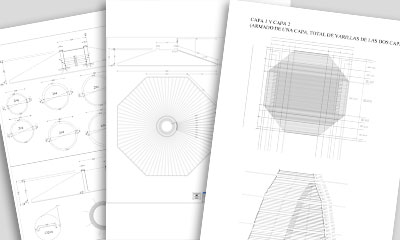

We do accurate quantifications.

- You will only pay for the amount of steel specified in your structural drawings.

- We develop an assembling plan for each structural component, defining the detail drawing and quantification by diameter.

-We write up a contract based on previous quantification and take responsibility for the stock by rod diameter for your construction.

Waste decrease.

HESA guarantees savings of at least 6% in construction waste, thanks to product variety and availability:

- ¼”, 3/8”, ½” & 5/8” rolled steel rod.

- ¾” and 1 ½” diameter bars are available in lengths other than 12 meters.

- Based on assembly and detail drawings, we conducted a bar optimization program for you and recommend the use of Type-2 mechanical connectors (Tekk-Steel), also available in HESA.

Quality Warranty.

Our replacement policy has 100% coverage for any material poorly prepared. Just contact us and we will make good on your warranty.

Productivity.

We take full advantage of our work cycle for prepared rods, so the productivity of your work can increase by at least 50%.

Price.

The use of prepared steel rod is 40% less expensive than typical labor cost. Ask our experienced consultants.

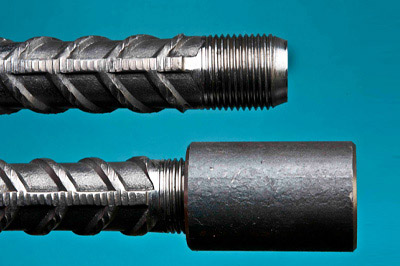

THREADED CONNECTORS

HESA optimizes your construction management and process by developing connectors for world-class quality bars.

Advantages

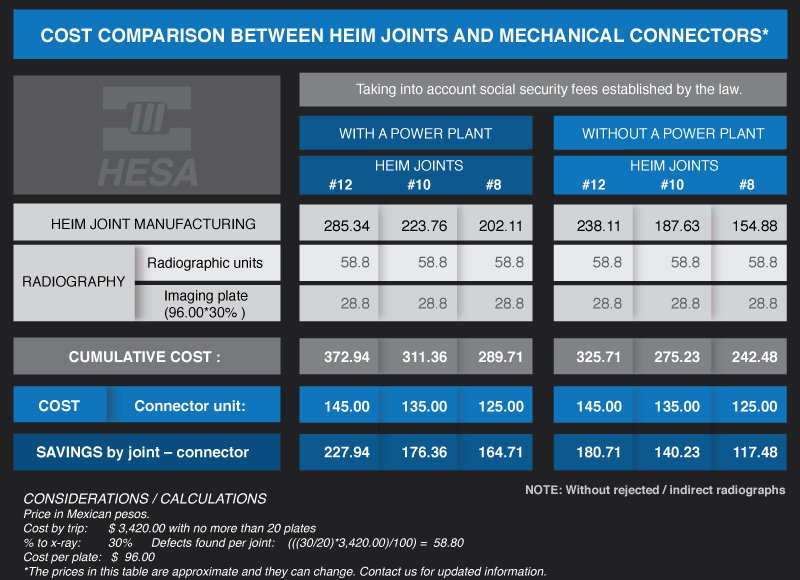

In addition to savings in typical labor management and steel rod waste, you receive the following advantages from our connectors:

Structural safety.

The elastic modulus of our bar-connector system is equal to that of the bar alone. No slipping occurs between the bar and connector threads.

Our rod jointing system Tekk-Steel 2 is certified by the Institute of Engineering of the National Autonomous University of Mexico (UNAM).

Price.

Our connector systems are at least 30% less expensive than a welded joint.

Quality.

The threads of our rods and couplers are made through rolling, ensuring strong exterior diameters and more traction resistance.

Service.

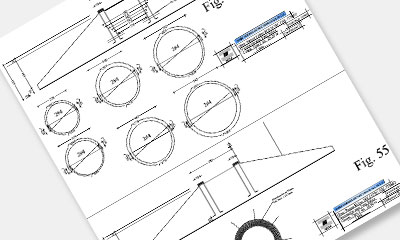

Our comprehensive service scheme consists of:

- Preparation of shop drawings and detail drawings for piers, footings, columns, concrete beams walls, and others.

- Preparation of bars based on detail drawings (cutting, forging, threading, bending and rolling).

- Shipping of the threaded bars and connectors to the construction site.

- Permanent stock of 400 tons of bars with lengths from 5.90 to 11.90 meters and diameters of 1”, 1 ¼” and 1 ½”.

- Production capacity of 2,500 bars a day.

Manufacturing and delivery.

Our manufacturing processes are based on the various preparation orders. Thus, you can file a precise order and minimize the amount of waste.

Rod jointing systems

It is because of this work system that our delivery time is one of the best in the market: 5 days at most for the first shipment to be dispatched.

• Verify the advantages of acquiring our prepared rods to optimize your construction costs.

• Look at the comparative table between welded joints and the Tekk-Steel connectors we use, in addition to other factors that influence the productivity of your work.

Price analysis comprises steel rod supply, detail engineering, on-site post-sale management and services, bar preparation, waste management during preparation and connector supply.

GRADE 42 REBAR WELDMESH & FRAMES

Grade 42 rebar weldmesh.

We manufacture weldmesh from Grade 42 steel rods, hot-rolled, in diameters from ¼” to 5/8”, according to the needs of your project for:

• Concrete & solid slabs.

• Retaining walls.

• Elevator & stairway walls.

Welded grade 42 rebar frames.

We manufacture welded Grade 42 rebar frames, hot-rolled, in diameters from ¼” to 5/8”, according to the needs of your project for:

• Reinforced concrete tie beams and pillars.

• Pilings.

• Sheet piling.

• Diaphragm walls built by the Milan method.

• Footings.

• ASHTOO concrete beams.

• T concrete beams.

• TT concrete beams.

VIDEO // On-site assembling